<small id="wg64m"></small>

Project Introduction

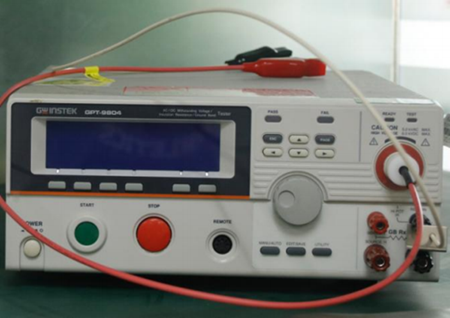

The withstand voltage test is a test to determine whether the insulation material and space distance of the device meet the requirements by giving the device a voltage higher than its rated voltage and maintaining it for a certain period of time. Withstand voltage test is an important part of electrical safety standards, used to find local defects, moisture and aging of product insulation.

experiment method

Withstand voltage test is one of the main methods to check the ability of electrical appliances, electrical equipment, electrical devices, electrical circuits and electrical safety appliances to withstand overvoltage. There are two kinds of frequency-withstand voltage test and DC voltage test. The test voltage of the power frequency withstand voltage test is more than double to several times the rated voltage of the equipment under test, and is not less than 1000V. Pressurization time: 1 minute for equipment with ceramic and liquid as main insulation, 5 minutes for equipment with organic solid as main insulation, 3 minutes for voltage transformer, and 10 minutes for oil-immersed power cable. In the DC withstand voltage test, the value of the leakage current at different test voltages can be used to draw the leakage current-voltage characteristic curve.

The difference between withstand voltage test and insulation test

The withstand voltage test and the insulation impedance test are connected in the same way. The withstand voltage test or high voltage test (HIPOT test) is used to verify the quality and electrical safety characteristics of the product (such as GB, UL, IEC, TUV, etc.) Standard) a 100% production line test. This type of test is conducted by subjecting the input power line of electrical products to high voltage for a specified period of time, and the safety agency specifies the magnitude of high voltage for each product type. This test also stipulates that "arc breakdown (or collapse) is not allowed" during the application of high voltage.

Insulation resistance is mainly to measure the equivalent resistance value formed by the related networks connected between the two end points and their surroundings. Insulation resistance refers to the resistance between the two parts of the conductor separated by insulating material, called insulation resistance In order to ensure the safety of the operation of electrical equipment, a minimum requirement is placed on the insulation resistance between conductors of different polarities (different phases) or between the conductor and the housing.

KC certification is a mandatory certification system implemented in South Korea for electronic and electrical products, aimed at ensuring that products comply with South Korea\'s safety and electromagnetic compatibility standards. The Korean market has strict quality control over imported goods, and smart rings, as electronic products, must pass KC certification in order to be legally sold in the Korean market.

CE-RED certification is a mandatory compliance requirement of the European Union for wireless devices. For smartwatches with wireless functions such as Bluetooth and Wi Fi, its importance is mainly reflected in the following three aspects.

The Brazilian market has enormous potential, but in order to successfully enter, ANATEL certification is an essential first step. As an authoritative standard certified by the Brazilian Communications Authority, ANATEL certification is not only a guarantee of product quality, but also a legal entry threshold into the Brazilian market.

The withstand voltage test is a test to determine whether the insulation material and space distance of the device meet the requirements by giving the device a voltage higher than its rated voltage and maintaining it for a certain period of time. Withstand voltage test is an important part of electrical safety standards, used to find local defects, moisture and aging of product insulation.

Get a quote